GLEEP, Western Europe's first nuclear reactor

08-09-2023

Prelude

GLEEP (Graphite Low Energy Experimental Pile was a low power experimental graphite pile, being the first nuclear fission reactor in Western Europe, as it was established in August 1947.

This blog post aims to pool together information about a fundamental, albeit often overlooked, milestone in the history of nuclear power.

GLEEP

Operation

GLEEP, a low-power reactor, had its design power limited to 100 kW, and operated continuously for most of its early lifetime. The low-power arrangements allowed GLEEP to operate without sophisticated cooling mechanisms, resulting in an air cooled, graphite moderated reactor, utilising natural uranium and uranium dioxide as its fissile materials.

Use

GLEEP was used mainly for experimental purposes, although for a brief period in its lifetime, it was also used for radioisotope production. However, due to it's low power design, GLEEP faced limitations in terms of neutron flux, and therefore a higher powered pile was conceived, BEPO.

Although designed to operate at 100 kW, GLEEP only ran at a peak of 80 kW for 18 months, producing radioisotopes. GLEEP operated at 3 kW for most of its operational life.

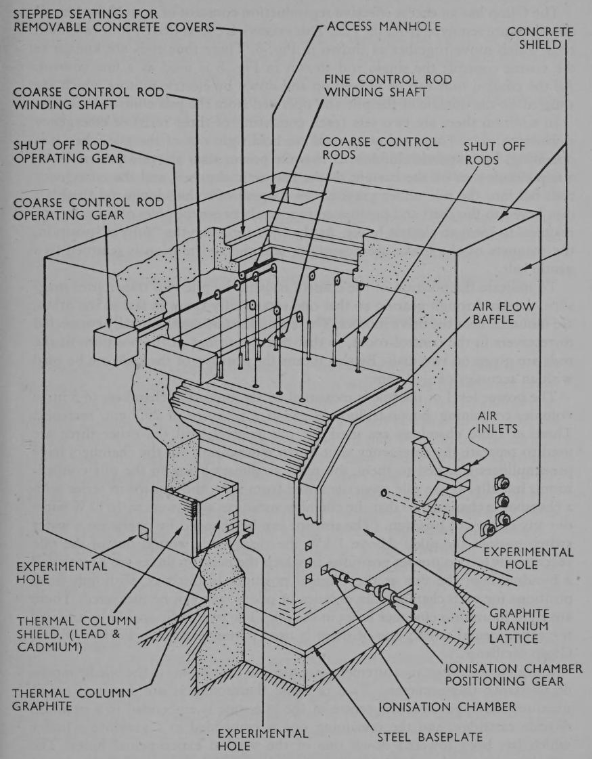

Dimensions

The reacting core, cylindrical in shape, had a length of 5.24m, and a radius of 2.86m. Rods were laid horizontally in a line lattice of pitch 18.4 cm, with a neutron reflector forming the "outer shell" of the octagon.

The pile was fitted with 505 tons of graphite in total, stacked in 40 layers, each layer being composed of a "parquet-floor like" grouping of blocks measuring 18.4 x 18.4 x 73.6 cm. Not all blocks are standard, however, with some blocks having chamfered edges.

Fuel

The fuel was laid out in the reacting core in such a way that the uranium metal rods occupied a radius of up to 1.75m, the outer region being loaded with uranium dioxide.

The uranium metal rods themselves were 30.48 cm long, and 2.29 cm in diameter, with a 0.007 cm aluminium coating applied in order to prevent recoil fission products from escaping. Uranium dioxide was pressed into pellets, then arranged into rods with the same dimensions as the previously mentioned uranium metal rods.

In total, GLEEP contained 12 tons of uranium metal and 21 tons of uranium dioxide.

GLEEP only underwent a single refueling procedure, in 1960.

Cooling

The pile was air cooled, equipped with a negative-pressure system capable of delivering 141 m³/min of air, which served not only to cool the uranium cartridges, but also remove radioactive argon-41 byproducts from the enclosure. Air was ejected through a short stack on the roof, and given argon has a relativately short half life (1.8 hours), no danger was posed to the public.

Nevertheless, through an argon chamber positioned at the top of the short stack, an excess in radioactive effluent was detected, which was not compatible with the "footprint" of the aforementioned argon. It was quickly determined that such effluent was caused by the uranium dioxide cartridges, even though the aluminium coating proved itself 99.5% efficient. Regardless, the uranium dioxide cartridges were cut off from the rest of the cooling system, as they did not have significant thermal output.

Control

Excess neutrons were controlled by 4 coarse control cadmium rods, and 1 fine control cadmium rod. The reactor was also fitted with 2 sets of emergency shutdown rods (commonly referred in modern systems as "SCRAM"), each with 3 rods.

Emergency rods were kept in place by magnetic force, an in case of an emergency, a breaker would trip, resulting in dropping of the rods.

Radiological safety

The reactor had a concrete biological safety shield 152cm wide on the sides, and 121cm wide on top. However, a 91cm air gap existed between the reacting core and the shield itself.

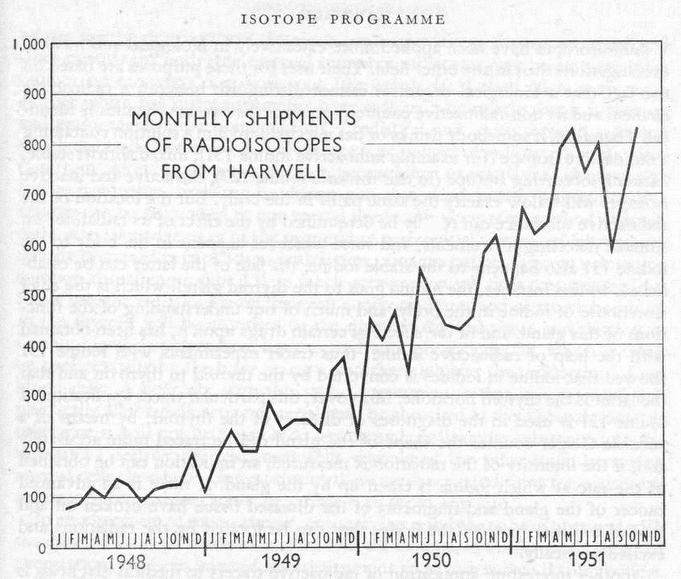

Isotope production

Although delegated to BEPO in later years, isotope production was one of the very first uses for GLEEP, with two machines in Harwell being used for electromagnetic separation. The first, built in 1948, could only produce stable isotopes with an atomic mass of up to 40, however, the second one, built in 1950, does not have the same limitations.

Isotopes produced at harwell were used in a number of fields, such as industrial, medicinal and academical. For instance, tracer techniques were still in development in the 1950s, and offered great promise. In industry, radioisotopes were used in dispersion of electrostatic charges, defect detection, and even quality control.

Isotopes were also exported to countries such as Austria, Australia, Argentina, Sri Lanka, Hong Kong, Israel, Norway, Pakistan, Italy, New Zealand, South Africa, Sweden, Switzerland, among others.

Decommissioning

GLEEP was shut down in 1990, however, fuel was only removed in 1994, and control rods/external equipment remained on site until 1995. Dismantling started in 2003, being completed in 2004.

The dismantling process involved the removal of 11500 spent fuel rods, 13500 graphite blocks (weighing a total of over 540 metric tonnes, sources do not agree on the weight of each graphite block), and a complete demolition of the enclosure. Most of the activity in the graphite pile, post removal, came from tritium and carbon-14.

The majority of waste produced from GLEEPs decommissioning has been low level waste, which was shipped to Drigg in Cumbria. 2000m³ of intermediate level waste will be stored on site. A cementation plant has been built to hand highly active liquid waste.

The UKAEA plans to have delicensed half of the currently licensed area by the end of the 2020s, with two wartime RAF hangars scheduled for demolished in the currently licensed area.

A video detailing the enclosure demolition can be found on Youtube.

Sources:

- https://www.rsis.co.uk/gleep-decommissioning-project-i131

- https://inis.iaea.org/search/search.aspx?orig_q=RN:42052529

- https://www.neimagazine.com/features/featuregleep-in-the-dark/

- https://archive.org/details/harwellbritishat0000harw

- https://web.archive.org/web/20160817073538/http://research-sites.com/news/2011-03-29/delicensing-confirmation